Find the Plastic Solutions for Your Applications

High-performance engineering plastics are widely used in many industries and applications due to their unique and excellent properties. Some application needs high mechanical strength parts, some demands exceptional chemical resistance, some components have weight limitation and some applications require material electrically insulation and working under extreme conditions. You can find all the corresponding professional solutions with the cooperation of Keward.

Keward provides a wide range of plastics and has extensive experience in many applications. We can help you to select the appropriate material, give you advice on design or directly machine the final components for you.

Solutions for General Industry

Corrosion resistance

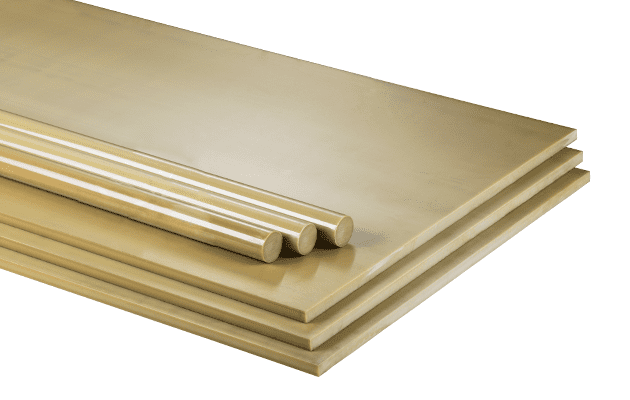

For some working environments that may have acid, alkali, or other corrosive substances, the mental alloy may not be the suitable material. Plastics like PEEK Virgin, PTFE Virgin, HDPE are the ideal materials according to different applications.

Narrow tolerance

Some components need to be very precise, besides the appropriate machining process, the high dimensional stable materials are also very important. Materials such as PEEK Virgin, Acetal Virgin, Ultem Virgin, PPS Virgin are typical plastics that are suitable for narrow tolerance applications.

Radiation resistance

Electromagnetic radiation resistance is considered one of the most important properties of high-performance plastics. The recommended materials are PEEK VIrgin, PI VIrgin, Ultem Virgin according to your applications.

Heat resistance

Many applications need materials that have excellent thermal stability. Some plastic’s continuous working temperature could reach 300℃. Material like PI HI, PEEK GF30, PPS GF40, PTFE Virgin is recommended.

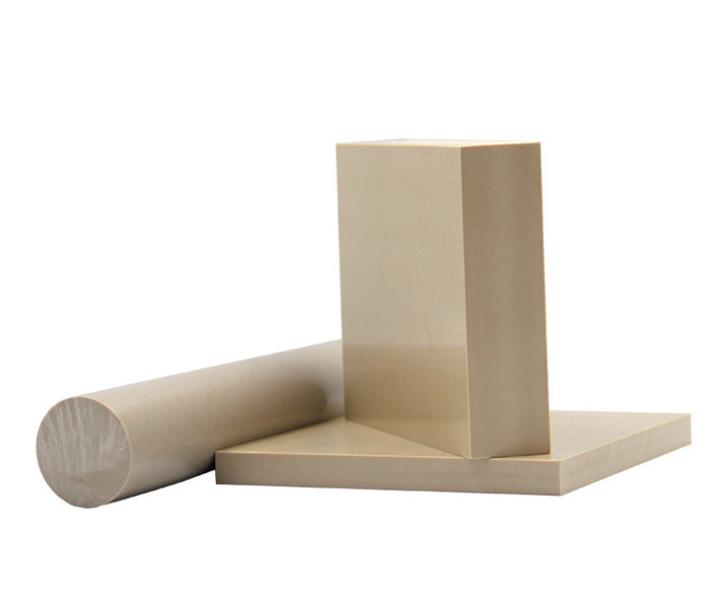

Materials for General Industry

PEEK Virgin

PEEK virgin is an unfilled semi-crystalline high-performance plastic with high continuous temperature, good mechanical strength, excellent dimensional stability, and exceptional chemical resistance.

Ultem 2300

PEI GF30 use the Ultem 2300 as the raw material to produce. It shows the properties of high rigidity, great mechanical strength and excellent dimensional stability.

PTFE Virgin

PTFE virgin is one of the most widely used high-performance plastics. It exhibits exceptional chemical resistance, very good slide and wears properties, excellent electrically insulation, and other benefits.

PEEK GF30

PEEK GF30 is a 30% glass fiber reinforced material based on PEEK virgin. Compared to PEEK virgin, the rigidity and wear resistance are improved, especially under the condition of high temperature and pressure.

Ultem Virgin

Ultem virgin has high mechanical strength, high rigidity, dimensional stability, and very good radiation resistance. It also has very good wave permeability and can be used in the telecom industry.

PPS GF40

PPS GF40 is a 40% glass fiber modified material based on PPS natural. For glass fiber reinforcement, it shows high rigidity, good wear resistance, great dimensional stability, and other benefits. Also could provide black color.

PA 6 Virgin

Nylon 6 is a good engineering plastic with the properties of good impact resistance, good machinability, good wear, and slide performance.

Acetal Virgin

Acetal virgin is a widely used material with great properties of high mechanical strength, good machinability, high rigidity and toughness. It can be used in many applications.