PEEK is a high-performance, semi-crystalline plastic which shows many unique properties.

PEEK plastic thermal properties

- Long term working temperature is 260℃

- Short term working temperature is 300℃

- The glass transition temperature is 150℃

- The melting temperature is 341℃

One of the most important characters of PEEK plastic is its exceptional high continuous working temperature. PEEK is also the most widely used high thermal stable plastic. We can see many PEEK plastics are used in the oil logging technology as the insulation components. The material requirements of the industry are high-temperature resistance, very good mechanical strength, and excellent insulation performance. PEEK is a plastic that combines all those characters.

PEEK plastic physical and strength properties

- Density is 1.31 g/cm3

- Tensile strength at yield is 116 Mpa

- Elongation at yield is 5%

- Flexural strength is 175 Mpa

- Compression strength is 102 Mpa

- The modulus of elasticity is 4200 Mpa

As we can see from the data, PEEK shows great mechanical strength and it is a plastic that combines rigidity and toughness. Due to its mechanical strength and lightweight, PEEK could be used in many applications to replace metal.

Moreover, PEEK plastic is also very easy to machine and shows good dimensional stability. So the material is often machined to precision components.

PEEK electrical properties

- Specific surface resistance is 1015 Ω

- Specific volume resistance is 1015 Ω*cm

- Dielectric strength is 73 Kv/mm

- The dielectric constant is 2.8-3.0

- The dissipation factor is 0.003

PEEK is a high-performance plastic with great electrical performance. The material’s dissipation is low and the dielectric constant is very stable, so these characters make the PEEK is widely used in the electrical connector industry, especially in high-frequency connectors applications.

Meanwhile, PEEK plastic also exhibits very great wave permeability. According to some research, the ratio of wave permeability of PEEK is beyond 95%. So the material is often used as a radome in military applications.

PEEK chemical resistance properties

PEEK has great chemical resistance properties, for the common chemicals, only 4 kinds of acids and bases could corrode PEEK.

For more PEEK chemical resistance performance, please check here.

PEEK other properties

- Flammability (UL94) is V0 grade

- Very good resistance to hot water

- Could withstand hot steam

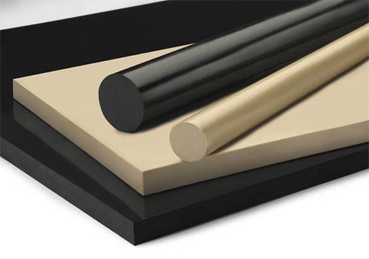

For PEEK shows these great properties, nowadays it is gradually widely used in many industries. Keward plastics could offer you PEEK rods, sheets, tubes, and machined components. The plastic material size we provide could cover a really wide range. There are always materials for you.