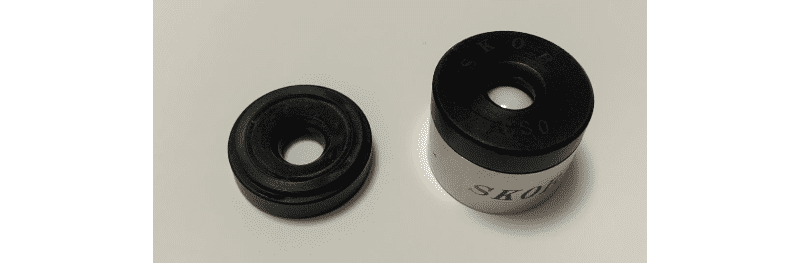

The water jet looms control valve allows you to move forward or backward as you weave without having to stop and adjust your fabric yourself. This saves time and ensures that your fabric remains taut throughout each pass of the weaving machine.

Why use PEEK CF30 instead of POM in the water jet loom control valve

Since the process of a waterjet loom control valve involves high temperatures and pressures, it is essential to use a material that withstands these conditions. The materials used for making water jet loom control valves are generally of two types – PEEK and POM (Polyoxymethylene). Both are thermoplastics that make excellent engineering materials but they have some differences in their properties. While PEEK is an expensive material, it can withstand high temperatures. The same cannot be said about POM which gets soft at relatively low-temperature levels. This makes it quite unsuitable for use as a part of a water jet loom control valve. On the other hand, POM is easy to mold and thus can be molded into complex shapes before being used for making water jet loom control valves.

Toughness and temperature resistance are the two key features that make PEEK carbon fiber-filled plastic an interesting alternative to POM when creating a water jet loom control valve. These properties help create a flexible material that is able to withstand extreme heat while maintaining its shape and function. Additionally, PEEK CF30 is also more resistant to chemical attack, which can be useful when working with chemicals or liquids that may cause corrosion in other materials.

PEEK CF30 is one of the best choices for water jet loom control valves, PEEK CF30 has the following advantages:

1. Good abrasion resistance, to protect the material and the machine

2. Good thermal stability, no deformation after a long time high-temperature working

3. Good hydrophobic and self-lubricating performance, high efficiency, and long service life of the bearing parts

4. The best creep resistance in the high-temperature working environment

5. Excellent chemical compatibility with hydraulic fluid

6. Good radiation resistance, no change after a long time of exposure to UV light.