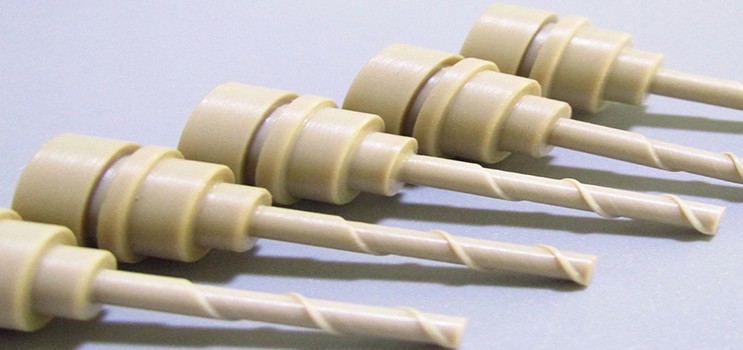

Dispenser screws are used to store and dispense glues, adhesives, sealants, and other materials. A wide range of dispenser screws is available for containers with capacities ranging from 30 milliliters to 20 liters.

The most common form of the screw shaft is threaded, which has one or more helical ridges around the shaft. These ridges push the molten plastic through the nozzle and into the mold cavity. This type of screw is called a single-flighted screw because it has only one set of helical ridges on its surface.

Plastic dispenser screws are a low-cost, high-performance solution when compared to traditional metal dispenser screws, like brass and steel. Plastic dispenser screws have all the same functionality as their metal counterparts with the added benefit of being non-corrosive and more lightweight. In addition, plastic dispenser screws are better for the environment than metal alternatives because they require less energy to produce.

Because some fluid contains hard substances like zirconia, if using normal plastic, then the lifetime is too short. For the wear resistance concern, we recommend using PEEK GF30 machined components.

The benefits of using PEEK GF30 plastic

PEEK GF30 (30% glass-fiber reinforced) is a semi-crystalline thermoplastic that has exceptional properties including high strength, stiffness, excellent dimensional stability, and resistance to chemicals, moisture, and high temperatures.

The benefits of using PEEK GF30 plastic in dispenser screws include:

Faster flow rate – The unique design of the PEEK GF30 screw enables it to dispense faster and more precisely than any other type of screw. The combination of an increased flow rate and reduced friction means that production can be increased significantly.

High heat resistance – The high heat resistance of PEEK GF30 allows for stronger, more efficient processing at high temperatures. This means production can be maintained at higher temperatures, increasing productivity.

Longer lifetime – The longer life of PEEK GF30 means that you will get more out of your investment before needing to replace the machine or parts, saving you money in the long run. Also. Compared with injection molding, the machining method can increase the lifetime of the product. Usually, use PEEK GF30 rod to machine and due to the complex thread, the five-axis CNC machining center must be used. We can not only provide the material but also offer a precision machining service. Check our PEEK machining guide for more details.

Non-stick – PEEK GF30 is a non-stick material and has a low coefficient of friction, which means it will not build up residue on surfaces such as conveyor belts or machine components, reducing waste and increasing productivity.