The petroleum logging instruments need to face very harsh working conditions that are usually high temperatures and high pressure. According to our practical experience, the usual working environment is 140℃~175℃ with 140mpa~160mpa. The polymers used in these instruments are required high mechanical strength, excellent electrical insulation properties, and good dimensional stability. So PEEK plastic is an ideal material for this application.

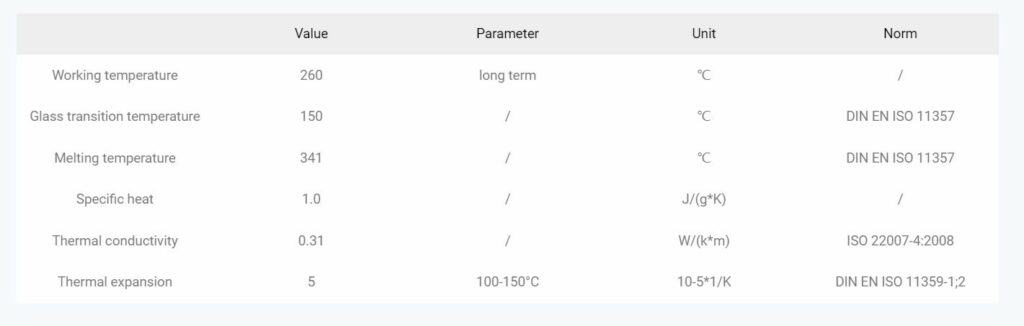

For logging tools, there are two commonly used PEEK plastic, the PEEK Virgin and PEEK GF30. According to the PEEK datasheet, this material has a high long-term service temperature, a high glass transition temperature, and excellent mechanical strength. The properties could be maintained even under the logging working condition. So PEEK plastic is widely used nowadays in the industry.

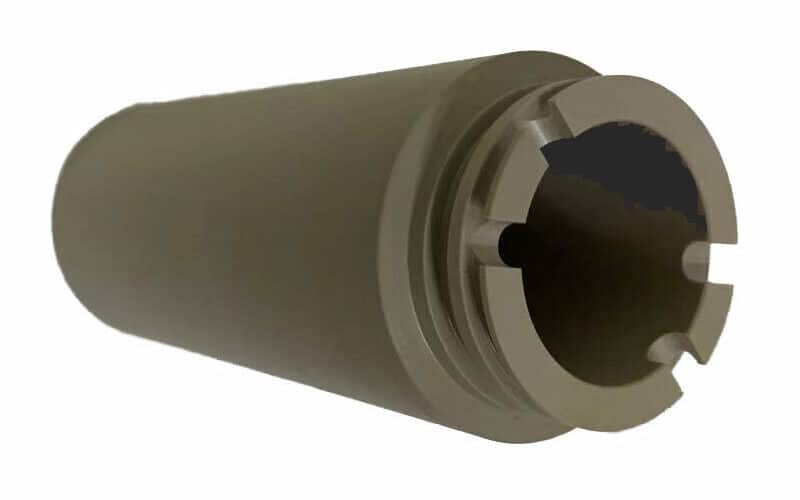

PEEK Used as Insulation Casing

The insulation casing can be found in electric logging instruments, such as a hard electrodes or dual later log equipment. The main function of the casing is to separate the two electrodes to avoid a short circuit. In this application, the material must withstand both high temperature and high pressure, and keep good electric insulation at the same time.

PEEK VS FRP

Compared to FRP, The most important advantage of PEEK is the low water absorption ratio. The relatively high water absorption ratio of FRP may cause insulation degradation. The properties of PEEK virgin and PEEK virgin black are the same, the only difference is the color. We provide the black type PEEK to offer customers another option.

PEEK Virgin VS PEEK GF30

Compared to PEEK glass fiber-filled, PEEK Virgin shows better toughness. But PEEK GF30 shows a higher elasticity modulus and higher stiffness. This makes PEEK GF30 more ware-resistant. So if the insulation ring needs to be directly touched with rock, then PEEK glass fiber-filled is a better choice.

Deformation at high temperature

Although PEEK has a long-term service temperature of 260℃, in the practical logging application the PEEK components may be deformed. This is because the working temperature of logging is usually beyond 150℃ which is the glass-transition temperature of PEEK plastic. When up to this temperature, PEEK will enter into a glassy state which means recrystallization will occur. Meanwhile, the insulation parts made of PEEK plastic also get the pressure of the instrument. The recrystallization plus high pressure under the well may cause the PEEK parts to deform.

To solve this problem, we recommend you replace PEEK virgin to PEEK glass fiber-filled plastic, which means PEEK GF30. Because the glass fiber will prop up PEEK macromolecule which could reduce the recrystallization ratio.