Polyether-ether-ketone, which is known as PEEK, is a high-performance, semi-crystalline plastic. This type of plastic exhibits a series of great properties, such as excellent chemical resistance, great mechanical strength, good dimensional stability, and so on. What should be mainly emphasized is that the long-term service temperature is up to 260℃(500℉). The most common PEEK plastics are PEEK natural, glass, or carbon fiber modified and the PEEK PVX.

PEEK natural

PEEK natural or the virgin form of PEEK is the most widely used PEEK plastic. Besides the great properties mentioned before, PEEK natural shows the highest toughness of the PEEK family. We can see the elongation at break is 15% and impact strength (Charpy) is n.b. Although the PEEK natural has high toughness, the modulus of elasticity of the material is only 4200mpa which is the lowest of the plastic family. Relatively low modulus means PEEK natural is ‘softer’ and does not wear resistance compared to other PEEK modified materials. So if you use PEEK natural under the frictional working condition, please beware of the material loss due to abrasion.

Meanwhile, for the chemical resistance, PEEK natural has the greatest chemical resistance among the PEEK family, only 98% concentrated sulfuric acid could dissolve PEEK natural and the plastic also shows different levels of resistance to different chemicals.

If you use the PEEK natural in the medical industry, the material also shows hydrolysis resistance to steam, which is an ideal plastic for the medical industry.

Another excellent property of PEEK is the insulation which is a core index for the oil logging technology. For some industries which the working condition is both high temperature and high pressure, like the oil and gas industry, which requests the material keep insulation, great mechanical strength under the extreme environment. As mentioned before, the glass transition temperature of PEEK is 150℃ and the long-term service temperature is 260℃. So PEEK is an ideal material fit for the extreme environment. We had used PEEK in the oil logging tools under the working condition of 170℃ plus 140mpa and the material was functioning well. However, if the temperature is up to 200℃ and relevantly the pressure is higher, then the PEEK GF30 is recommended.

Also, besides all the mechanical and chemical excellent properties mentioned before, PEEK plastic shows great electronic performance as well. It has a very stable dielectric constant and low dissipation factor which makes the material possible to use in telecom technology. We had successfully used the PEEK natural in the electronic connectors. Meanwhile, this plastic also shows great wave permeability. We had machined the material into radome and the performance was beyond expected.

The lightweight of PEEK plastic should be mentioned as well. The density of the material is only 1.31g/cm3. In the aerospace industry, plastic is always used for structural components due to its lightweight and good mechanical strength.

PEEK 30% glass fiber filled(PEEK GF30)

PEEK GF30 is a plastic that uses short-chain glass fiber to fill in the PEEK natural. Because of the glass fiber, the most difference between PEEK GF30 and PEEK natural is the modulus. The modulus value of PEEK GF30 is 6300mpa which is the highest among the PEEK family. The high modulus value means PEEK GF30 has higher stiffness and wear resistance compared to PEEK natural. Relevantly, the higher stiffness makes the plastic more brittle. The elongation at break of PEEK GF30 is 5%. So the material is suited for the application that requests rigid friction rather than impact.

What’s more, the deformation at high temperature and high pressure of PEEK GF30 is lower than PEEK natural due to the glass fiber. When the temperature is above 150℃, which is beyond the glass transition temperature of PEEK, the glassy state of the material would happen. Under this circumstance, the recrystallization would happen and the mechanical strength of PEEK would be decreased. But for the PEEK GF30, because of the glass fiber, the recrystallization ratio would reduce. So if PEEK natural and PEEK GF30 are under the same high temperature and high-pressure working conditions, the deformation of PEEK GF30 would be lower. We had successfully used the PEEK GF30 in the oil logging tools under 220℃ plus 180mpa and the material was functioning well.

PEEK 30% carbon fiber modified(PEEK CF30)

PEEK CF30 is a 30% carbon fiber-filled plastic base on the PEEK natural. Compared to the PEEK natural, the carbon fiber increases the modulus and maximumly keeps the toughness of the material at the same time. For PEEK CF30, the modulus of elasticity is 6000mpa and the elongation at break is 10%. So PEEK CF30 is a material that keeps very high stiffness and relatively high toughness.

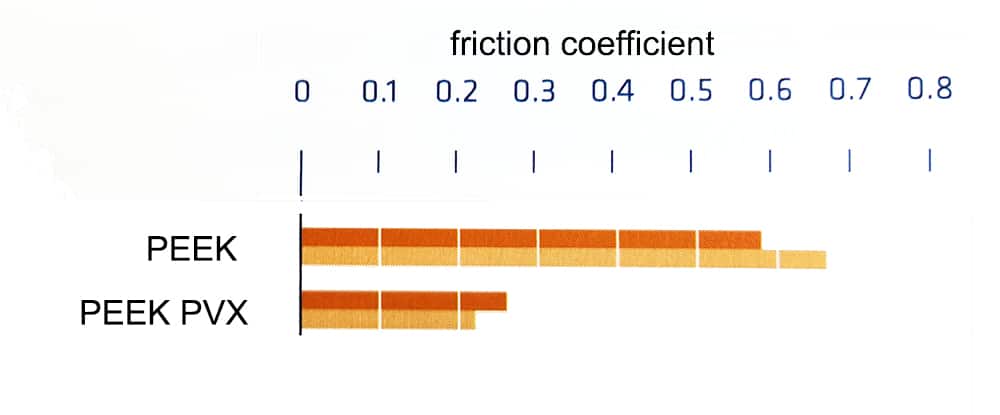

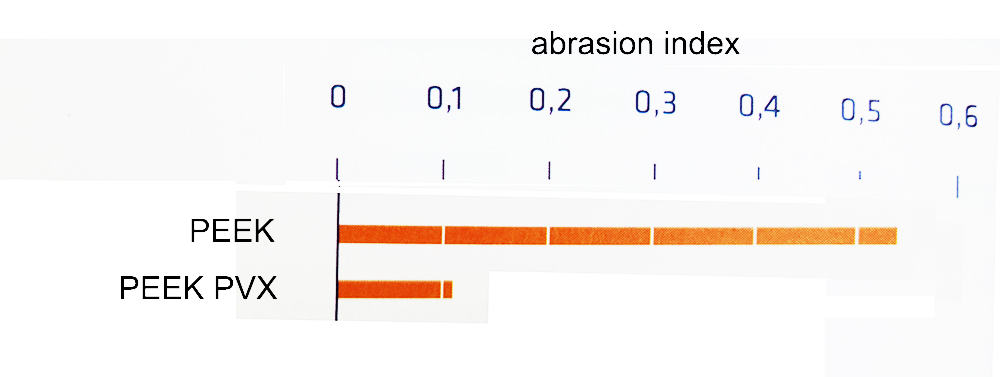

In addition, the carbon fiber-modified PEEK shows great wear resistance and very good friction performance. PEEK CF30 which compared to PEEK GF30, the property of wear resistance is even better. Moreover, the carbon fiber could conduct heat more effectively. So PEEK CF30 is suited for the sliding application.

Like PEEK natural, the PEEK CF30 has great hydrolysis resistance in steam and boiled water. So the material could be used in medical technology.

PEEK 10% graphite+10% PTFE+10%carbon fiber(PEEK PVX)

The PEEK PVX is adding graphite, PTFE, and carbon fiber based on the PEEK natural. Increasing slide and wear properties is the main aim. The friction coefficient and the abrasion loss of PEEK PVX are the lowest among the PEEK family. So this material fits in the application of sliding. Also, some people call PEEK PVX as bearing grade PEEK.