Polyether-ether-ketone or PEEK is one of the high-performance polymer materials with high mechanical strength, good impact strength, excellent chemical resistance, and outstanding dimensional stability. For today’s application, all these fantastic properties mentioned before are essential. The equipment’s working conditions are always under temperature and high pressure in the coal mining industry. Usually, the pressure is...

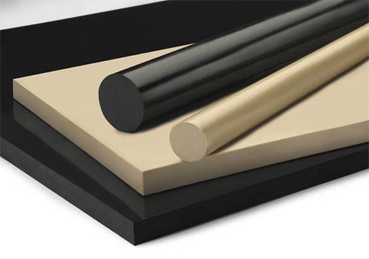

PEEK plastic is a high-performance material with excellent mechanical strength, lightweight, and outstanding chemical resistance properties. Check the PEEK page for more information. For the table below, A=Excellent B=Fair. The moderate effect is not recommended for long-term use. C=Poor. Not recommended for any use. N/A=Information not available Send us Email for PEEK material rod, sheet...

For connectors, especially for the high-frequency and radio-frequency connectors, besides the excellent design and manufacturing technique, another critical factor in determining whether the products are good is the plastic because the function of plastic in the connectors applications is insulation. Usually, the connectors are tiny, and the typical diameter ranges from 3mm to 10mm. It...

Why commonly use PEEK plastic? The PEEK coil frame is a structural component whose primary function is to provide structural support for the wire. Considering the insulation, the coil former usually uses plastic instead of metal. At the same time, the polymer should have outstanding mechanical strength, good dimensional stability, and a high service temperature...

The petroleum logging instruments need to face very harsh working conditions that are usually high temperatures and high pressure. According to our practical experience, the usual working environment is 140℃~175℃ with 140mpa~160mpa. The polymers used in these instruments are required high mechanical strength, excellent electrical insulation properties, and good dimensional stability. So PEEK plastic is...

Polyether-ether-ketone, which is known as PEEK, is a high-performance, semi-crystalline plastic. This type of plastic exhibits a series of great properties, such as excellent chemical resistance, great mechanical strength, good dimensional stability, and so on. What should be mainly emphasized is that the long-term service temperature is up to 260℃(500℉). The most common PEEK plastics...

What is back up ring Back up ring plays a very important role in the seals. You can tell its function from the name: it back up the O-ring. Usually, the backup rings are just structural support that keeps the O-ring away from the extrusion gap in hardware. Actually what seals is the O-ring and...

PEEK is a high-performance, semi-crystalline plastic which shows many unique properties. PEEK plastic thermal properties Long term working temperature is 260℃ Short term working temperature is 300℃ The glass transition temperature is 150℃ The melting temperature is 341℃ One of the most important characters of PEEK plastic is its exceptional high continuous working temperature. PEEK...